2500 Hydroform Series:

Industrial Force, Modular Footprint

Unlock complex geometries and aerospace-grade precision without the overhead of traditional heavy machinery. Our Hydroform line uses single-sided elastomeric forming to produce complex, non-linear bends and deep embossments with professional repeatability.

From our Small Parts Cell 12" unit to the high-capacity 24" Work Horse, our patent-pending design delivers the lightest, most power-efficient industrial rubber pad forming presses on the market. We engineered the "pit" out of the process—delivering massive tonnage that sits directly on your shop floor.

Choose Your Capability

Utilizing intuitive touch screen CNC controls, every model in our lineup delivers consistent pressures of 400 to 2,500 PSI of forming pressure, providing the right amount of force no matter the material, tooling, or shape.

The Makers Equipment Advantage

Revolutionary Portability

We shrank the footprint, not the capability. Our presses are fully self-contained and engineered to be the lightest industrial-grade units available. Whether you are in a high-rise urban facility or a rural shop, you can install these machines on a standard flat floor without specialized rigging, concrete pits, or expensive site prep.

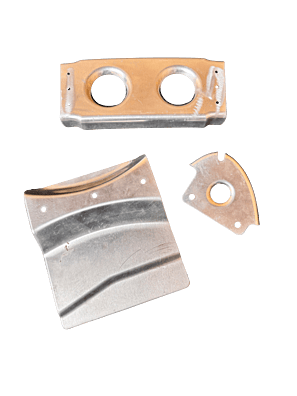

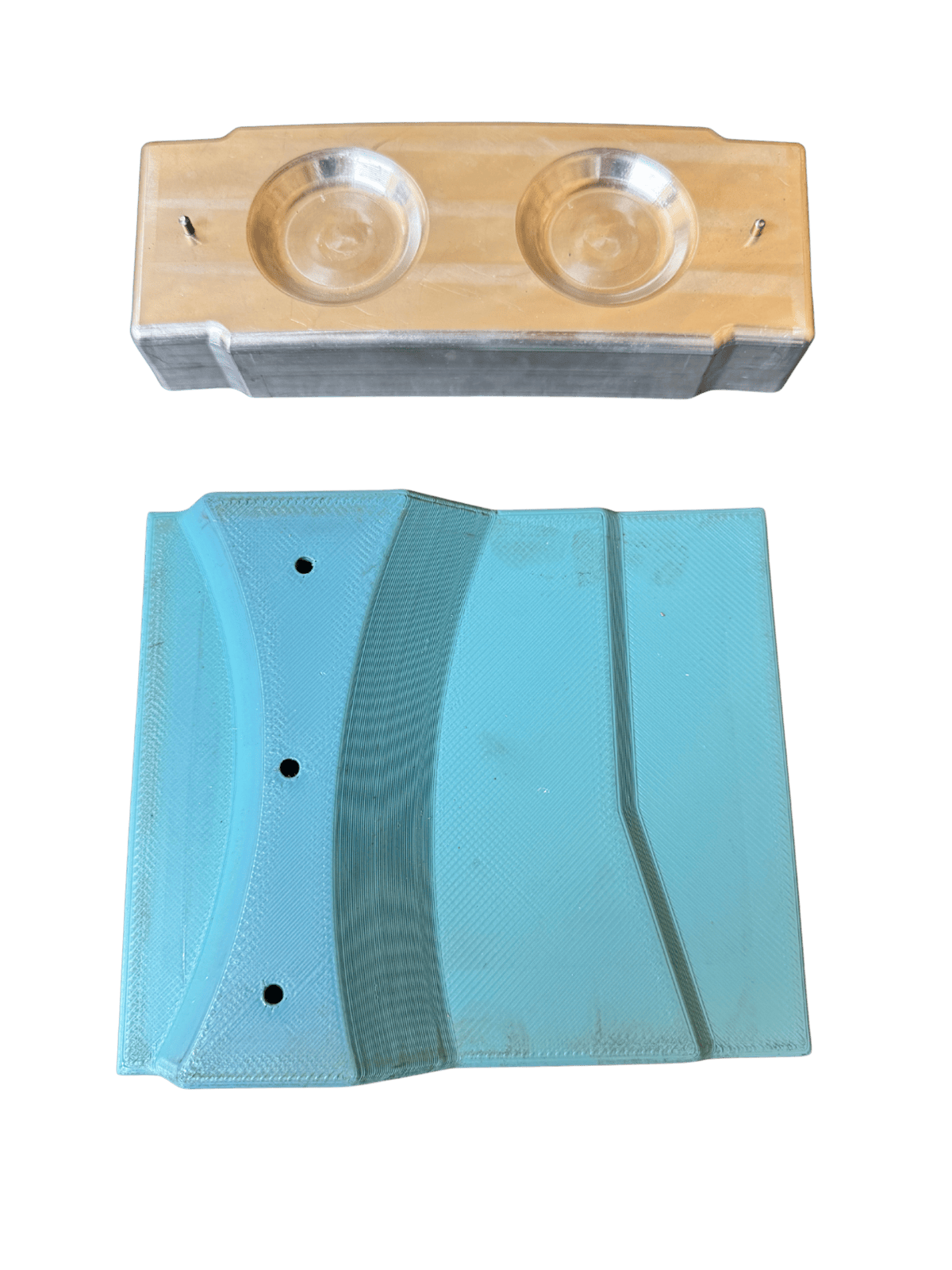

Rapid, Low-Cost Tooling

Hydroforming (elastomeric forming) eliminates the need for expensive matched-die sets. Because our system uses a flexible rubber diaphragm as the "universal" female die, you only need a single-sided male form.

Tooling Freedom: Form parts using dies made from Aluminum, Steel, 3D-printed plastics, Epoxy, or even Hardwood.

Speed to Market: Go from CAD design to a finished metal part in hours, not weeks.

Universal Power Efficiency

Don't let your utility company dictate your output. All Makers Equipment presses are engineered for extreme power efficiency, capable of running on Single Phase or Three Phase power. We bring heavy industrial activity to any location with a standard electrical drop.

Transparent Pricing

| Model | Forming Box | Foot Print (LxWxH) | Price |

| 12-2500 | 12" Diameter x 5" Tall | 35" x 27" x 65" | $50,000 |

| 18-2500 | 18" Diameter x 5" Tall | 46" x 36" x 65" | $95,000 |

| 24-2500 | 24" Diameter x 5" Tall | 52" x 42" x 65" | $125,000 |

*Ask about our Educational Institution and Government Discount

Standard Features on All of our Hydroform Press

CNC Controls

An Allen-Bradley CNC controller enables the operator to adjust the maximum forming pressure from 400 - 2500psi to accommodate a variety of tooling and part materials. These parameters can be saved for up to 200 part numbers enabling consistent results on repeat production parts.

Safety Cage & Door

Move beyond the risks of open-post presses. Every Makers Equipment hydroform press features a standard safety enclosure and a door-interlock system. Our controls prevent all ram movement unless the safety door is fully closed, protecting your team from high-pressure pinch points.

Simplified Maintenance

We believe you shouldn't be held hostage by proprietary parts. That’s why Makers Equipment uses commonly available, off-the-shelf components for most wear items. For non-standard parts, we maintain a 100% in-stock guarantee with next-business-day shipping to ensure a breakdown doesn't turn into a bottleneck.